Follow along on a new custom home build

Ranch house completed may 2018

Enjoy the pictures of the completed home, and then scroll down to see each step of the Ranch House project!

Have you ever wanted to build your own custom home, but weren’t sure about the process?

You’re in luck!

KLH Homes, Inc. started a new build in 2017 from open land to construct a beautiful ranch home and the homeowners have kindly allowed us to share the process with you!

Click to jump to the start of the construction process.

All cabinet doors and drawers in pantry, kitchen, and baths have quiet self-closing hinges and soft closing drawer slides.

Follow the New Build with this Gallery of the Construction Process for this beautiful home.

Discussions, dreams, budgets, a meeting of minds, bids, contracts and finally the PLANS!

The Building Permit acquired!

The homeowners are making decisions. KLH helps with selection of exterior finishings, roofing, trim, etc., so the footings and support walls will be sized appropriately.

The basement is excavated.

Every house needs to begin with a strong foundation (and a basement)! KLH Homes works with several qualified concrete and foundation companies to get you the best product at the best price. We are on hand at each project to supervise and deal with any problems as soon as they arise so you don’t have to!

The footings are poured.

The drainage installed.

The garage footings poured.

The forms for the basement walls are set.

KLH field supervisor and our subcontractor kept a close eye on the weather forecast, and rescheduled the pour of the basement walls for after the anticipated snow, so we didn’t have any problems with the concrete pour or the concrete cure!

Once the snow melted, concrete trucks were back and began the final pour for the foundation, the basement walls.

The forms have been removed and the walls are now freestanding, the exterior of the walls water-proofed, garage drain set, and the window wells set for the basement windows.

The KLH plumbing subcontractors are roughing in the plumbing for a basement bath that the homeowners plan to finish with KLH a few years down the road.

The KLH exterminating subcontractor is pretreating the soil for control of subterranean termites.

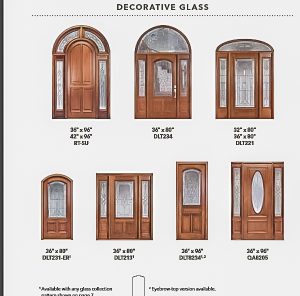

More decisions for our homeowners. Windows and doors and metal facia need to be ordered now. They went with Pella, at KLH suggestion. The Pella expert spent a lot of time explaining the products and offering ideas. So many decisions!! Often a decorator is consulted.

The KLH concrete subcontractor is back-filling the garage area in preparation for the pouring of the concrete basement and garage floors the next day. Note the drainage pipe in the center of the garage floor is now covered.

The Basement floors are poured. (The basement will be finished n a year or so according to our clients plans.) KLH Owner, Zach Luka, is onsite daily to inspect the work.

The garage floor is poured, as well.

.

The lumber is delivered for the start of the framing.

.

.

As builders this is one of the most exciting times for us! Up until this point our clients have trusted, based on drawings and estimates, that we can build their dream home. Now framing has begun and they can see the size of their rooms – they can visualize furniture placement and layout as they walk the site with our crew! (Basement walls and support structure is completed.)

Floor joists and floor sheathing are installed. KLH Homes Owner, Zach Luka, leads the KLH framing crew, and is onsite throughout the layout and framing.

The basement stairs are framed so our clients are able to see the full potential of their unfinished basement. (It also provides access for our subcontractors who need to access the basement for utilities, etc.)

The main floor framing begins. Rooms start to take shape.

Trusses are delivered to be set for the roof structure.

The interior walls are framed. Once all the skeleton is in place, we began siding with OSB to give a strong base for exterior materials and the interior drywall.

Preliminary trusses are set to prepare for the main trusses to be set with the aid of a crane.

The trusses are set, and the roof decking began.

The roof decking continues, roofing felt is being applied to protect the decking. Shingles are on order, scheduled for delivery, so the KLH Crew can start applying them the next day. By the way, the home owners had asked KLH to protect the front yard trees and perennials, so they have been very careful. The roof line on the rear turrets is complicated, so the crew has been taking extra time to make sure the sight line is exact.

After a few weeks of serious on and off rain:

Our clients home is now completely “dry” – which is a blessing after all this rain! The house is wrapped, the roof is finished, and windows are installed. The next steps include dirt work and landscaping around the home and the building of the back deck. Subcontractors will be coming and going in the next few months working on exterior stonework, plumbing, and electrical. It’s always surprising for our clients how much can change in just 3 short months!

Our clients wanted a bit of a change to the rear deck, so Zach suggested a second pop-out section to reflect the deck under the covered porch. The home owners wanted an area for eating (right outside of the sliding doors at the dining room) and an area for a fire-pit, which is now on the other side by the master bedroom.

The interior is taking shape, with the windows defining the space.

The siding is complete, awaiting the masonry finish on the front of the residence.

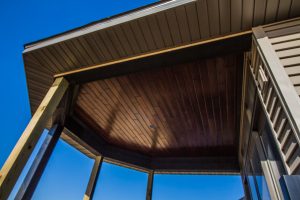

The rear deck, with its view of the homeowner’s corn field is almost finished. Stairs will exit the deck in the center. Railing will be added on the covered portion as well. The deck material has been stained two separate colors to add an architectural definition and a separation of space. The ceiling of the covered portion reflects the deck surface.

The stairs are built leading from the deck to the rear yard. The gorgeous Pella Front Entry Door system selected by our homeowners has been stained and installed. The bricks have been delivered for the masons to start the brick front to the residence.

The brick facade to the front has been started.

Since they are out in the country, the homeowners requested lights to illuminate the exterior of the home. Zach suggested “under eve lighting” . Our homeowners were delighted with what the electricians installed on the garage side, and decided to add these lights on all four sides.

The brick facade to the front is just about finished

The garage door has been installed with a door opener that can be operated from within the vehicles (as usual), a keypad on garage exterior, or from the homeowners’ cell phones.

The rear deck steps and railing are finished.

Meanwhile on the interior, the electrical pre-wire and in-wall plumbing is started. The alarm system and cable are also pre-wired. The homeowners are invited to do a walk-thru to make sure the lights, switches, outlets, and shower fixtures are where they want them to be. The Master Shower will have “His & Her sides”, with multiple custom shower heads selected individually for the husband and wife on opposite ends of the shower.

The insulation has been installed in the walls, and blown in the attic.

The drywall has been delivered.

The rooms are really taking shape and the homeowners are excited to see the individual rooms, flow, sizes, etc. It is looking like a home now! The open floor plan is just what they wanted, and now it is easier to visualize.

The drywall has been hung, taped and the ceiling textured. The Master Bedroom has the beautiful ceiling to reflect the profile of the pop-out window wall. The fireplace is installed.

The painting has been started after a meeting with the interior designer that works with KLH Homes to help select colors and floor suggestions. The owners have now selected the carpet, tile, and hardwood; light fixtures, plumbing fixtures; the doors, trim and cabinets are on order.

The interior paint has been completed, and the master bath tile has been set.

The landscapers seeded the lawn as soon as the site was graded so the grass would get a head start before winter.

The weather cooperated and the grass looks luscious.

The custom crafted interior doors were made by a local mill-work shop that is also doing the interior trim. All the doors and trim will be stained to match the front entry door.

Floor tile has been laid in the kitchen, dining room, baths, pantry, entryway, laundry, and mud room. Engineered hardwood was laid in the living room and hallway and quickly covered with a thick rolled cardboard to protect it.

Light fixtures, ceiling fans, and recessed fixtures have been installed.

Interior work continued on through the winter, including finishing the amazing walk-in-closet with His & Her custom cabinetry on either side, and a built-in three way mirror.

Zach has custom designed all the cabinet layouts (closet, baths, laundry, kitchen and pantry) with input from the homeowners. He has also built all of the cabinet boxes, drawers, shelves, etc. while having the doors crafted by the same custom local mill-work shop that is also doing the interior trim. All the master bath, kitchen, and pantry cabinets and doors and trim will be stained to match the rest of the interior trim. The walk-in-closet, laundry, and hall bath cabinets are painted a crisp white.

Custom cabinetry allows total freedom of design without being constrained by stock cabinet sizes and minimum options.

The butler’s pantry has been completed. The homeowners’ are avid cooks and wanted a butler’s pantry off of the kitchen with plenty of cabinets for storage and a long counter top for kitchen small appliances to be stored as well as used. Multiple electrical outlets were provided for a coffee maker, a blender, a crock pot, a food processor, a stand mixer, etc. They also wanted doors to separate it from the kitchen, but not make it too closed off. Zach suggested doors with slightly obscure glass panels, and they loved how they turned out. The kitchen cabinet layout and island design have been completed and approved by the homeowners, and Zach has started building them.

The laundry has almost been completed, with custom cabinetry, including space to hang clothes, and niches for laundry bask

The custom cabinetry for the master bath is in progress and ready to be set in the vanity. The doors are being crafted at the mill-work shop.

The entertainment center cabinetry has been completed. The stone face for the fireplace is the next project.